Vaniman’s microabrasive sandblasters have zillions of applications — one of which, we recently learned, is wood pipe carving.

Check out our latest video (transcript below) from when Chris Plummer of Copperbeard Pipeworks paid us a visit:

Featured Products:

Sandblasting & dust collection:

-

Master Problast 3 – 80060$1,559.30View Details

Master Problast 3 – 80060$1,559.30View Details -

Abrasive Vac w/ Lg. Accumulator – 10660$974.46View Details

Abrasive Vac w/ Lg. Accumulator – 10660$974.46View Details -

Mobile Problast – 80017$390.10View Details

Mobile Problast – 80017$390.10View Details

Blasting media:

Accessories & more:

Transcript:

Recently we were lucky enough to be visited by Chris Plummer of Copperbeard Pipeworks. Chris hand carves wooden pipes and was looking for a tool to increase efficiency with his processes and also enhance the level of detail he’s able to extract from the wood. He called us up to see if he could give our blasters a test drive, to which we happily said yes! After some experimenting with various sizes and nozzle tips, he found what he was looking for, and we learned a lot about grains and cross grains in wood — and maybe, just maybe, picked up a new obsession…

CHRIS P.:

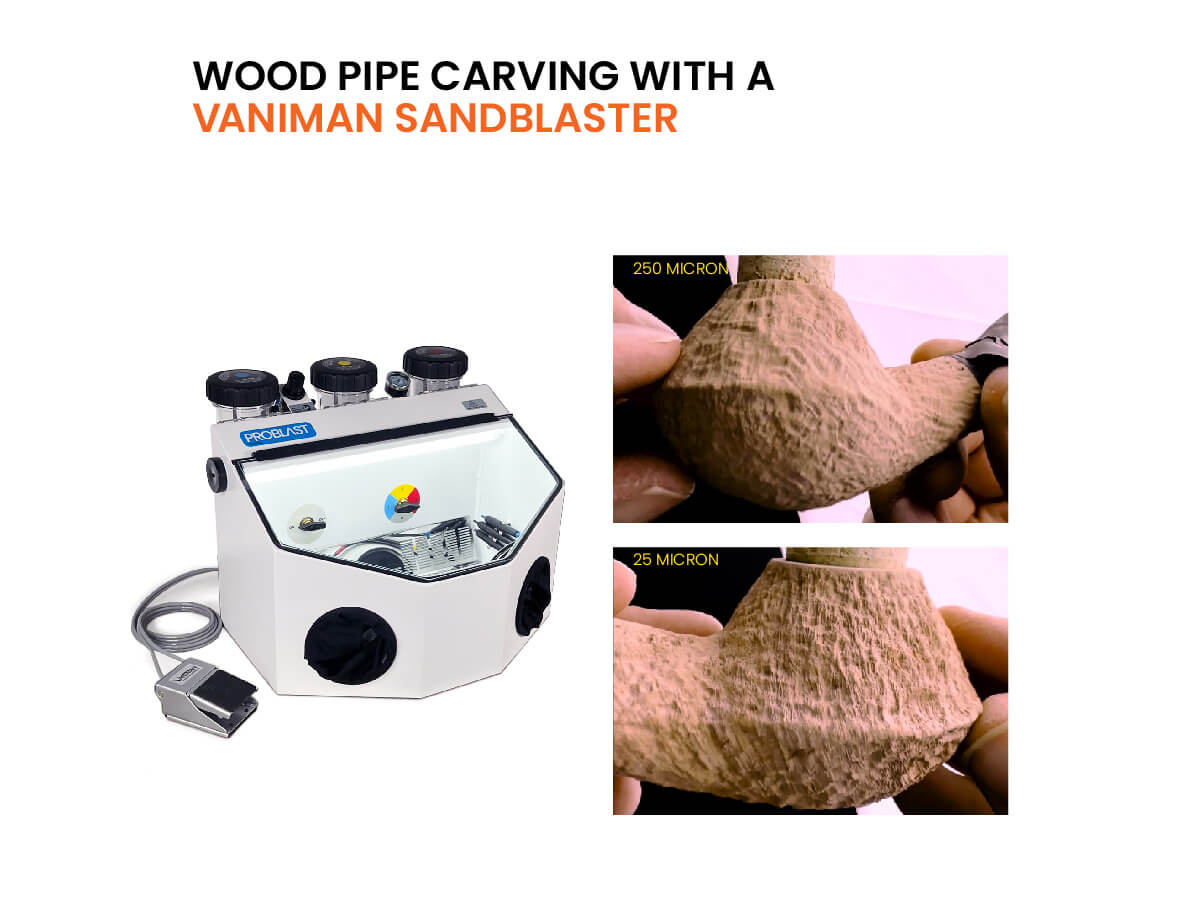

Alright, so I switched over media. I’m now on the 250 aluminum oxide. So this is ten times bigger than what I was just cutting with. And I’ve got a section here, I’m just gonna showcase what exactly it looks like when I’m cutting with a bigger micron.

BIL G.:

Oh, you’re not on.

CP:

I’m not on. Let me turn the system on. There we go, now I’m pressurized.

BG:

And, uh, do you want to try a slightly less PSI? Just because, again, 90 PSI can sting…

CP:

Let me see how bad it stings at first, and then that way I can give them a, uh, a proper “Oh my god, that did not tickle…” Alright, so, let’s see — OH YEAH, that does not tickle.

I’m able to work much further away, you can see I’m able to cut a little bit faster, remove some of those other layers a little bit quicker. The detail is definitely not there, but I’m able to reveal some of those features a little bit faster than what I was working before.

So this would be, on JT Cooke’s website, this would be the equivalent of Step 1 that he talks about — let’s just reveal the grain, show what the wood looks like, let’s identify our sections, where’s our cross grains, where’s our actual grain running as well, clean up some of those sand pits…

You can actually see the media size on here now, actual — looks like fine, fine salt.

So on the master blaster system, there’s a really nice air blasting system, too, so when you’re working on your unit, you can clean it off and start looking at the detail that you’ve been doing.

So one of the things I do notice, with the 25 micron and now with this one, is there’s kind of like a terminal depth that you can reach. It only kind of, like, cuts so far to only show so much of the detail before you have to kind of step down to the finer one.

And on the soft end grain, it definitely penetrates a lot faster, a lot quicker on the softer pieces, and the harder parts definitely stick out.

Yeah, I’m hybridizing shapes to get to this one shape, but then what I liked is I really liked that ridge, because—

BG: Yeah, it’s really pronounced on that side.

CP: Right, and that’s where I was like, I’m gonna really dig into this to show just like how this grain is coming across here. The root was actually like right there, and so you have this, like, cross-grain that is growing this way, as the tree was growing this way. So it’s like you have two different grain patterns that are happening. So, like, here you have that — this is the cross grain. But then this is the way that it was actually, like, growing the fibers at the same time.

And this brush really accentuates the ability to bring those grains out. So let’s just go by a little area, just like this…

There we go.

BG: Alright, so this side was blasted over with 250 micron aluminum oxide. And there’s quite a bit of texture already. You can very clearly see the grain and the cross-grain together, and you can see the kind of texturing you’ll get with it.

Now on this same piece of wood, on the other side, we have 25 micron aluminum oxide, and as you can see, it’s a world of difference in terms of the detail that you get into. It’s a much finer grain, so it will get in between these ridges that you can see. And it will get deeper down, too. Chris here, he’s been blasting for a while with — you were at 90 PSI?

CP: Yeah.

BG: So just about as strong as our blaster can handle, getting those teeny tiny particulates as far down as possible…and the detail is out of this world.